English

PCD DRAWING DIES

Product Description

PCD DRAWING DIES

1. PCD DRAWING DIES

Polycrystalline Diamond dies

for drawing of wires from 0.050 mm to 30.00 mm

PCD dies offer a high resistance to wear and an excellent wire surface finish. The dies can be used in ferrous and non-ferrous wire drawing applications.

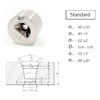

2. PRODUCT PARAMETER (SPECIFICATION) OF PCD DRAWING DIES

PCD Dies with PCD Blanks

| mm | Inches | ADDMA | Maximum Diameter |

| 0.100-0.400 | 0.0039-0.0157 | D6 | 0.4 |

| 0.200-0.800 | 0.0079-0.0315 | D12 | 0.8 |

| 0.200-1.000 | 0.0079-0.0394 | D12 | 1.0 |

| 0.500-1.500 | 0.0197-0.0591 | D15 | 1.5 |

| 0.800-2.000 | 0.0315-0.0787 | D18 | 2.0 |

| 1.200-3.100 | 0.0472-0.1181 | D21 | 3.1 |

| 2.000-4.400 | 0.0591-0.1732 | D24 | 4.4 |

| 3.300-5.800 | 0.1299-0.2183 | D27 | 5.8 |

| 5.100-7.600 | 0.2008-0.2992 | D30 | 7.6 |

| 8.000-11.000 | 0.3150-0.4331 | D33 | 11.0 |

3. PRODUCT FEATURE OF PCD DRAWING DIES

Soft Wire:

Gold, silver, platinum, brass, phosphor bronze, aluminum, etc.

Hard Wire:

Iron wire, stainless steel wire, nickel wire, chrome wire, molybdenum wire, tungsten wire, copper clad steel wire, etc.

4. BENEFITS

Polycrystalline Diamond Wire Drawing Die is the longest die life of all materials, which can provide the highest production efficiency and reduce downtime. It is suitable for all applications from large drawing to ultra-fine drawing,with predictable wire surface quality.

Imported diamond blanks include Japanese SUMIDIA and American COMPAX(GE) .

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos