English

TC Tungsten Carbide Diamond Wire Drawing Die

TC Wire Drawing Dies (Tungsten Carbide Wire Drawing Dies) are widely used in applications that require high temperature, impact resistance and only short-term use. This is made possible by the low price of tungsten carbide dies. Because of its ease of processing and low cost, tungsten carbide is also selected as the die blank material for most special-shaped molds and stranding dies.

Product Description

Wire Drawing Die

TC Wire Drawing Dies (Tungsten Carbide Wire Drawing Dies) are widely used in applications that require high temperature, impact resistance and only short-term use. This is made possible by the low price of tungsten carbide dies. Because of its ease of processing and low cost, tungsten carbide is also selected as the die blank material for most special-shaped molds and stranding dies.

Feature:

1. High wear resistance and Good polishing

2. Small adhesion and coefficient of friction

3. Low energy consumption

4. High corrosion resistance.

5. The hardness of the carbide dies is compared lower than the PCD dies

6. The wear resistance of the carbide dies is lower and the life of the dies is shorter than the PCD dies.

Advantages:

1. High hardness, good thermal conductivity, low coefficient of friction

2. Low cost, used in some highly lossy, hard wire processing processes

3. Uniform wear when used

4. Tungsten carbide module can withstand a high temperature of 2800 degrees C

5. Fast delivery time at about 7-10 days after receiving your payments

Tungsten Carbide Wire Drawing Dies Application:

It is widely used to drawing all kinds of wire such as electronic devices, radar, television, instrumentation and aerospace, such as the use of high-precision wire, as well as commonly used tungsten wire, molybdenum wire, stainless steel wire, wire cable wire and a variety of alloy wire .

Parameter Table

| Die Blank Size(mm) | Hole Size(mm) |

| φ13×10 | 0.40-2.10 |

| φ16×14 | 2.11-3.10 |

| φ22×18 | 3.11-6.00 |

| φ30×21 | 6.01-10.50 |

| φ40×25 | 10.51-16.50 |

| φ50×28 | 16.60-26.00 |

| φ60×35 | 26.10-36.00 |

| φ75×35 | 36.10-50.00 |

| φ90×35 | 50.01-60.00 |

| φ12×8 | 0.80-2.70 |

| φ15×10 | 1.30-4.50 |

| φ20×14 | 3.50-6.40 |

| φ25×18 | 5.70-8.70 |

| φ30×22 | 7.70-11.50 |

| φ35×25 | 9.70-14.00 |

| φ40×27 | 12.50-17.50 |

| φ12.7×11.4 | 0.80-4.60 |

| φ15.8×15.2 | 0.80-5.30 |

| φ18×17.7 | 1.00-8.90 |

| φ19.5×19.5 | 5.80-9.00 |

| φ25.4×20.8 | 8.80-12.30 |

| φ30.1×20.8 | 9.00-15.00 |

| φ38.1×25.4 | 11.50-17.30 |

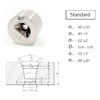

Shapes/drawing Reference

| Hole size(mm) | Regular Case size(mm) |

| 0.15-1.00 | 25*10 |

| 1.00-2.00 | 30*15/20 |

| 2.01-3.00 | 40*25 |

| 3.01-4.00 | 40*25 |

| 4.01-5.00 | 40*25 |

| 5.01-6.00 | 40*25 |

| 6.01-7.00 | 40*25/50*30 |

| 7.01-8.00 | 50*30 |

| 8.01-9.00 | 50*30 |

| 9.01-10.00 | 50*30 |

| 10.01-12.00 | 50*30 |

| 12.01-14.00 | 60*40 |

| 14.01-16.00 | 60*40 |

| 16.01-18.00 | 60*40 |

| 18.01-20.00 | 80*50 |

| 20.01-25.00 | 80*50 |

| 25.01-30.00 | 80*50 |

| 30.01-35.00 | 100*60 |

| 35.01-40.00 | 100*60 |

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos