English

Diamond Micro-powder

Domestic top-quality single-crystal diamond materials are used as raw materials;

Product Description

Diamond Micro-powder

1. Product Introduction of Diamond Micro-powder

Product Characteristics:

Domestic top-quality single-crystal diamond materials are used as raw materials;

Technical data such as static pressure strength, abrasive performance and thermal stability are higher than standards of the industry;

Round and smooth crystal; fewer absorbed particles on powder surface; no bar- or plate-shaped particle;

Extremely narrow range of granularity distribution and excellent granularity control;

Special processing techniques enable the content of impurities to be about 1/100,000.

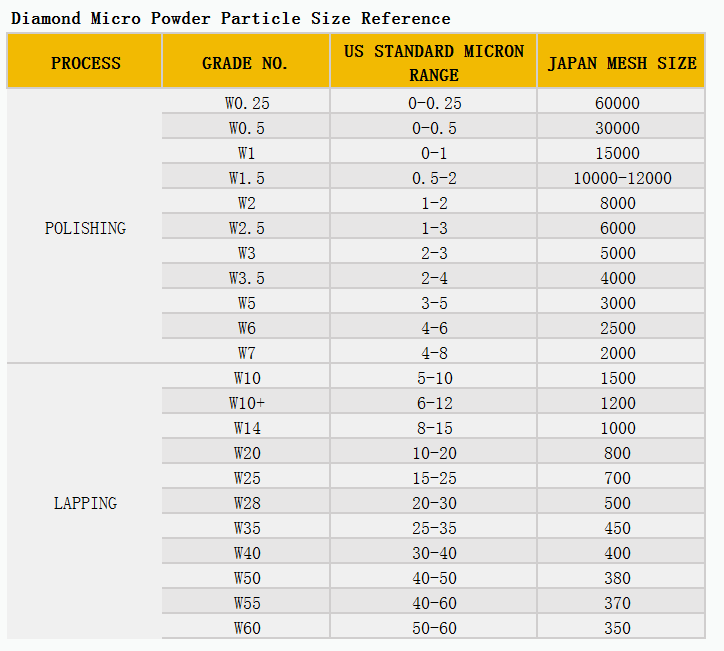

2.Product Parameter (Specification) of Diamond Micro-powder

3.Product Feature And Application of Diamond Micro-powder

Application:

The products are suitable for applications in industries that have high demands on grinding and polishing such as the precision equipment industry, as well as in sectors that are strict with impurity content, like electroplating and production of polycrystalline diamond compacts

Advantages:

·Crystal with sharp edges

·hard and crisp texture

·Even granularity distribution

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos