English

ND DRAWING DIES

Product Description

ND DRAWING DIES

1. ND DRAWING DIES

Natural diamond is the hardest material among the world's known materials. It has extremely high hardness, good thermal conductivity and photothermal properties.

Natural diamond wire drawing dies is mainly used for drawing fine and ultra-fine wires,or it is widely used in applications requiring excellent wire surface finish and good heat dissipation performance.

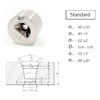

2. PRODUCT PARAMETER (SPECIFICATION) OF ND DRAWING DIES

The Selection of Natural Diamond Dies

| New Die Range | Recut Range | |||

| mm | inches | stone# | mm | inches |

| 0.050-0.099 | 0.0019-0.0039 | 1# | 0.100-0.200 | 0.0039-0.0079 |

| 0.100-0.199 | 0.0039-0.0078 | 2# | 0.201-0.300 | 0.0079-0.0118 |

| 0.200-0.299 | 0.0079-0.0118 | 3# | 0.301-0.400 | 0.0119-0.0157 |

| 0.300-0.399 | 0.0118-0.0157 | 4# | 0.401-0.500 | 0.0158-0.0197 |

| 0.400-0.499 | 0.0157-0.0196 | 5# | 0.501-0.600 | 0.0197-0.0236 |

| 0.500-0.599 | 0.0197-0.0236 | 6# | 0.601-0.700 | 0.0237-0.0276 |

| 0.600-0.799 | 0.0236-0.0315 | 8# | 0.801-0.900 | 0.0315-0.0354 |

| 0.800-0.999 | 0.0315-0.0393 | 10# | 0.901-1.099 | 0.0355-0.0433 |

| 1.000-1.199 | 0.0394-0.0472 | 12# | 1.101-1.299 | 0.0433-0.0511 |

3. FEATURES

(1) Natural diamond wire drawing dies, abbreviated as ND, are naturally formed within the earth at high-pressure and high-temperature conditions. Because of its extremely rigid lattice, it can be contaminated by a few types of impurities such as boron and nitrogen.

(2) Natural diamond dies provide superior quality, hardness, accuracy and a long service life for each die. They yield precision wire with an excellent surface finish, enabling high drawing performance and low power usage due to low friction.

4. BENEFITS

(1) Long lasting tooling, ideal for long production runs

(2) Wire remains round, even with significant wear

(3) High surface quality matching your requirements

(4) High-accuracy dies available

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos