English

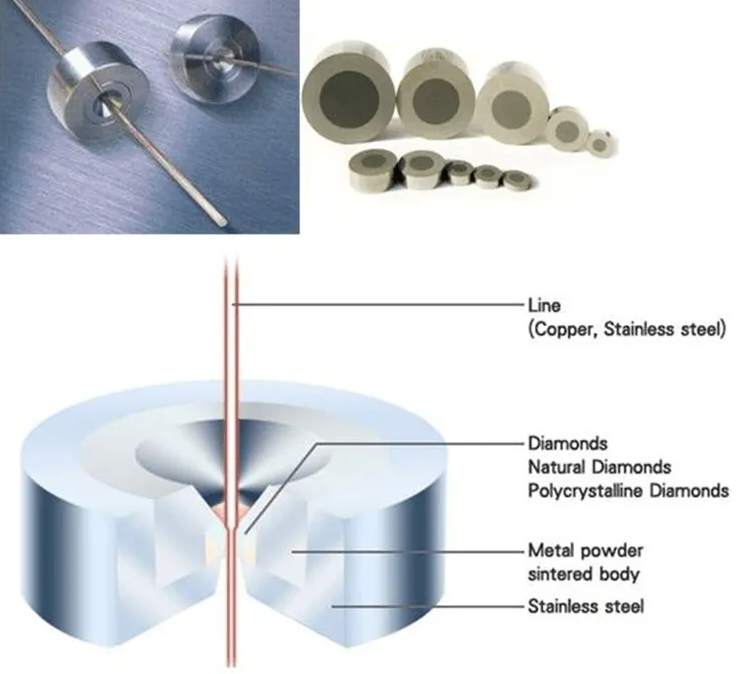

Diamond PCD ND Wire Drawing Dies

ND Wire Drawing Dies (Nature Diamond wire drawing dies), it’s die blank raw material diamond is la type diamond. These diamonds contain certain nitrogen impurities (0.1% order of magnitude), and these nitrogen impurities are combined into small aggregates. With very high hardness and good thermal conductivity and photothermal properties, in the industrial field is widely used in conductor industry. Its physical properties are: density 3.515g/cm3; hardness: 1.25-10.76GPa.

Product Description

Wire Drawing Dies

ND Wire Drawing Dies (Nature Diamond wire drawing dies), it’s die blank raw material diamond is la type diamond. These diamonds contain certain nitrogen impurities (0.1% order of magnitude), and these nitrogen impurities are combined into small aggregates.

With very high hardness and good thermal conductivity and photothermal properties, in the industrial field is widely used in conductor industry. Its physical properties are: density 3.515g/cm3; hardness: 1.25-10.76GPa.

Feature:

1. We select each natural diamond carefully to ensure the good quality of the die core, coupled with precise orientation when mounting

2. With special plastic polishing equipment and unique mold hole production process

3. It will ensure that each mold has precise size, perfect hole type, in the filament, ultra-fine wire or high-surface finish wire pull-out always has excellent performance.

Advantages:

1. High hardness and good wear resistance

2. High-efficiency, smoothness, and durability predicted

3. A wide range of grain and nib sizes

4. Perfect characteristics of crack-proof and good polishing of wire or tube surface

5. Fast delivery time at about 7-10 days after receiving your payments

ND Wire Drawing Dies Application:

Recommended for drawing of all types of wire with high surface quality requirements: platinum-palladium wire, gold wire, silver wire, copper, aluminum, nickel, tinned copper, tungsten, copper-aluminum alloy and other non-ferrous metal wire.

Parameter Table

| TYPE | DIE SIZE (mm) | STANDARD TOLERANCE (um) | STANDARD CASES | |

| A | B | |||

| ND DIES | <0.04 | 0.5 | 25 | 5 |

| 0.04-0.07 | 0.5 | 25 | 5 | |

| 0.08-0.19 | 1 | 25 | 8 | |

| 0.2-0.39 | 1 | 25 | 8 | |

| 0.4-0.59 | 1 | 25 | 10 | |

| 0.60-0.10 | 2 | 25 | 10 | |

| >1.0 | 3 | 30 | 15 | |

| PCD DIES | D6 | 0.10-0.15 | 25 | 7 |

| D12 | 0.10-0.80 | 30 | 15 | |

| D15 | 0.50-1.50 | 30 | 15 | |

| D18 | 1.00-2.30 | 30 | 15 | |

| D21 | 1.60-3.40 | 30 | 15 | |

| D24 | 2.60-4.60 | 42 | 20 | |

| D27 | 3.00-5.80 | 55 | 24 | |

| D30 | 4.00-11.20 | 55 | 24 | |

| D33 | 6.00-12.50 | 60 | 28 | |

| D36 | 8.00-13.50 | 70 | 35 | |

| D | 12.00-22.00 | 70 | 35 | |

| D | 20.00-32.00 | 85 | 40 | |

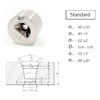

Shapes/drawing Reference

|

Wire |

Hard Wire |

Soft Wire |

|||

|

Regular Standrad |

Stainless steel |

Copper-clad steel |

Tungsten, tantalum |

Copper wire |

Aluminum wire |

|

Antry Angle |

80° |

80° |

80° |

80° |

80° |

|

Lubrication Angle |

35° |

35° |

35° |

35° |

35° |

|

Reduction Angle |

14°±2° |

14°±2° |

12°±2° |

16°±2° |

18°±2° |

|

Bearing Length |

0.2-0.5D |

0.2-0.6D |

0.2-0.8D |

0.2-0.5D |

0.2-0.5D |

|

Relief Angle |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

25°±2° |

|

Exit Angle |

60° |

60° |

60° |

60° |

60° |

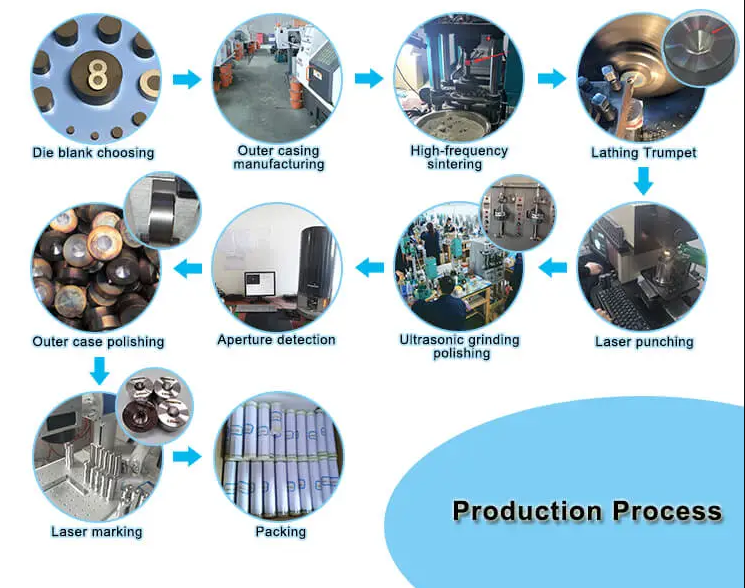

Photos

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos