Which kinds of drawing mold are divided into, where to use?

Which kinds of drawing mold are divided into

where to use?

Which kinds of drawing mold are divided into, where to use?

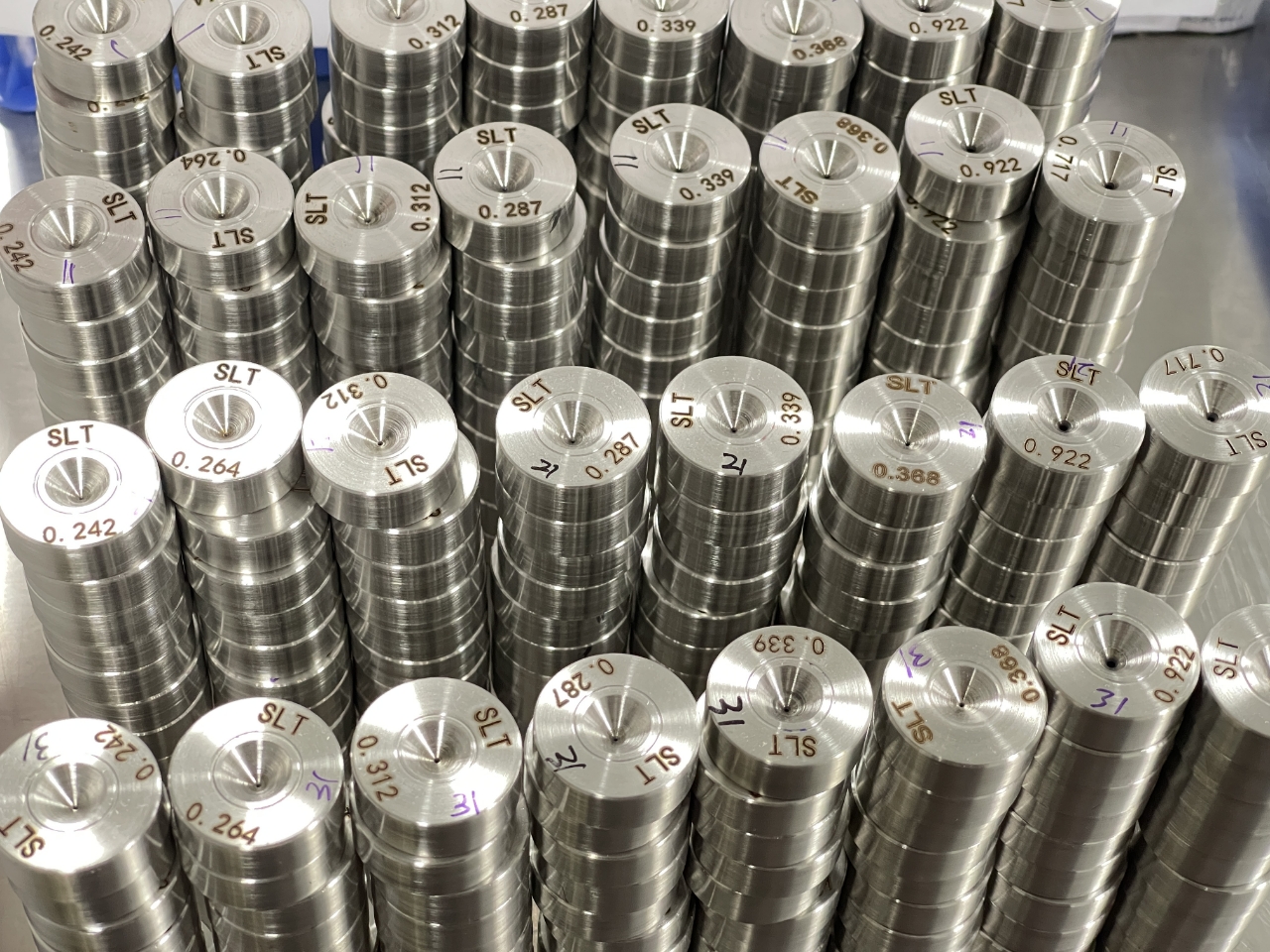

Wire drawing die is widely used in electronic devices, radar, television, instruments, aerospace and other industries of high-precision wire, as well as applied in tungsten wire, molybdenum wire, stainless steel wire and other industries of wire drawing die. Secondly, wire and cable wires and various alloy wires are made of diamond wire drawing die.

The working principle of the wire drawing die is to thin the wire from the coarse, and gradually reach the desired size of the die. This special mold is a wire drawing die. Drawn die seals are usually made of natural diamond and synthetic diamond (synthetic diamond including ge, pcd, synthetic materials, etc.). Copper wire drawing die belongs to soft wire drawing die. There are also hard wire drawing molds, such as tungsten wire drawing. The compression zone Angle of the copper wire drawing die is generally 16-18 degrees, and the length of the ruler is 30-40%, while the compression zone Angle of the tungsten wire drawing die is relatively small, generally 12-14 degrees, and the length of the ruler is 60-70%.

Diamond wire drawing dies are made of natural diamond, so they are equipped with diamond wire drawing dies. Strong wear resistance, long service life. The production process of drawing die insert includes pressing die, drawing die and turning.

The drawing die includes special drawing die, hard alloy drawing die, polycrystalline drawing die, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos

Changzhou Shen Litong Mould invites you to visit the exhibition

From August 27th to 29th, 2025, at SHANGHAI NEW INTERNATIONAL EXPO CENTRE,the 12th China International Wire&Cable Industry Exhibition (Hall E1, G21), Shen Litong Dies sincerely invites you to visit, exchange and offer guidance, and jointly explore new developments in the industry.

Read MoreOptimizing Your Wire Drawing Process: Selecting the Ideal Die Configuration for Material & Application

The wire drawing process is a critical metal forming operation that reduces the cross-section of wire by pulling it through a series of progressively smaller dies.

Read MoreCommon Wire Surface Defects: Causes and Die-Related Solutions

Abrasions or Built-up Edges (BUE): Accumulation of wire material (e.g., copper, aluminum) on the die surface, which then scratches subsequent wire.

Read More