Introduction of the wire drawing die hole structure

Introduction of the wire drawing die hole structure

Introduction of the wire drawing die hole structure

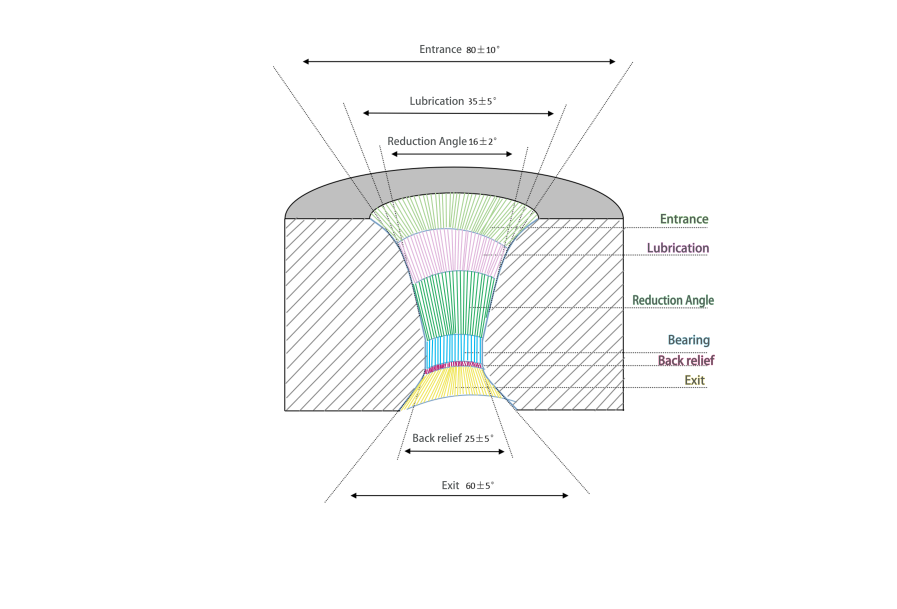

Entrance zone: Drawing materials enter the dies through this area. Generally it is an arc in order to avoid drawing materials scratched by the dies.

Lubrication zone: It is for lubricant storage and drawing material lubrical lubrication which is conducive to smooth drawing.

Reduction zone: It is a plastic deformation zone for metal drawing which key dimension is length and angle. Smaller length will make drawing metal cause more pressure to reduction zone.This will significantly increase the tensile stress and accelerate the wearing of the dies which will influence drawing effect. Reduction zone length differs in different drawing material,diameter and lubrication. The selection principle is: 1)the length should be shorter in drawing soft metal wire compared to drawing hard metal wire; 2)the length should be shorter in drawing small diameter wire compared to drawing big diameter wire; 3)the length should be shorter in wet drawing compared to dry drawing reduction zone angle:bigger angle will increase the tensile strength and the hardness of drawing material while will decrease the bending and torsion. Reduction zone angle should be smaller in drawing steel while it should be bigger in drawing non-ferrous metal and carbide.

Bearing length: Drawing material gets its final size through bearing length, Bearing length differs in different hardness, section and lubrication of the drawing material. If bearing length is too long, it will increase the friction which heightens the die temperature and then influences the die life. It will also increase the tensile stress which causes the rising of shrinkage rate and breakage rate in drawing as well as powder consumption; if bearing length is too short, bearing changes will affect finished size in drawing.

Generally 1)bearing length is shorter in drawing soft metal material compared to drawing hard metal material; 2)bearing length should be shorter in drawing small diameter wire compared to drawing big diameter wire; 3)bearing length should be shorter in wet drawing compared to dry drawing.

Back relief and exit: Exit is the last part where drawing material leaves from the dies. It is to protect the bearing length form cracking. Exit should not be too short, otherwise the outlet will be easily broken; back relief means to ensure that drawing metal will not scratch exit and influence the wire quality ;during adjusting the dies the sharp part connecting exit and bearing must be ground to be an arc in order to avoid the wire scratched when passing through the dies.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos

Changzhou Shen Litong Mould invites you to visit the exhibition

From August 27th to 29th, 2025, at SHANGHAI NEW INTERNATIONAL EXPO CENTRE,the 12th China International Wire&Cable Industry Exhibition (Hall E1, G21), Shen Litong Dies sincerely invites you to visit, exchange and offer guidance, and jointly explore new developments in the industry.

Read MoreOptimizing Your Wire Drawing Process: Selecting the Ideal Die Configuration for Material & Application

The wire drawing process is a critical metal forming operation that reduces the cross-section of wire by pulling it through a series of progressively smaller dies.

Read MoreCommon Wire Surface Defects: Causes and Die-Related Solutions

Abrasions or Built-up Edges (BUE): Accumulation of wire material (e.g., copper, aluminum) on the die surface, which then scratches subsequent wire.

Read More