How to repair drawing die regularly

How to repair drawing die regularly

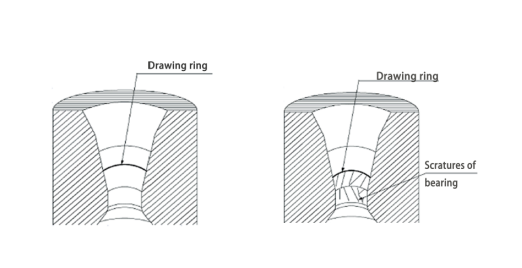

In the long-term use of the wire drawing die, the die surface is subjected to strong friction and erosion of the metal wire, which inevitably produces wear. The most common is the appearance of annular grooves (dents) at the entrance of the wire in the work area. The appearance of the ring groove of the wire drawing die aggravates the wear of the die hole, because the small particles of the core material peeled off due to loosening on the ring groove are brought into the working area and sizing area of the die hole by the metal wire, which acts as an abrasive and enters The wire of the die hole exacerbates the wear of the die hole like a grinding pin. If the repair is not carried out in time, the ring groove will continue to accelerate and expand, making the repair more difficult. There may even be cracks in the deeper part of the ring groove, causing the dies to completely be scrapped.

We know from experience that it is very economical and cost-effective to work out a set of norms and standards, strengthen dally maintenance, and often perform maintenance on the drawing dies. Once there is any slight wear on the dies, polish it in time, it will take less time to restore the dies to the original polished state, and there is no obvious change in the die hole size.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos

Changzhou Shen Litong Mould invites you to visit the exhibition

From August 27th to 29th, 2025, at SHANGHAI NEW INTERNATIONAL EXPO CENTRE,the 12th China International Wire&Cable Industry Exhibition (Hall E1, G21), Shen Litong Dies sincerely invites you to visit, exchange and offer guidance, and jointly explore new developments in the industry.

Read MoreOptimizing Your Wire Drawing Process: Selecting the Ideal Die Configuration for Material & Application

The wire drawing process is a critical metal forming operation that reduces the cross-section of wire by pulling it through a series of progressively smaller dies.

Read MoreCommon Wire Surface Defects: Causes and Die-Related Solutions

Abrasions or Built-up Edges (BUE): Accumulation of wire material (e.g., copper, aluminum) on the die surface, which then scratches subsequent wire.

Read More